Find Event Packages

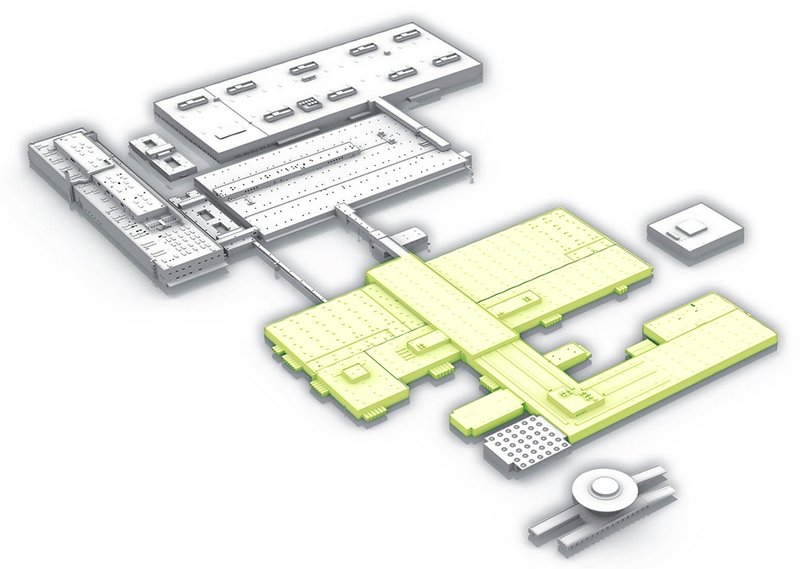

The assembly line

On the assembly line, we turn the

To guarantee efficient, high-capacity production in the face of such complex tasks, professional logistics is key. Consequently, we rely on a “just-in-sequence” strategy (JIS), which means that the sequence of vehicle bodies delivered to our factory corresponds exactly to the production sequence. System suppliers deliver pre-assembled and model-specific components at the same time. As a result, we can implement the proven concept of lean inventories.

1. Interior line

This is the first step on the assembly line, when the doors are removed from the bodies in order to work on them separately on the door line. If the doors were to remain on the vehicle, many of the subsequent interior line assembly steps could not be performed. Following this step, the cockpit, one of the largest complete modules, is installed in the

Other components assembled in this step include sliding or panorama roofs, control units and the rooflining, including grab handles and sun shades. The final step on the interior line is training the key, which is put into the ignition here for the first time.

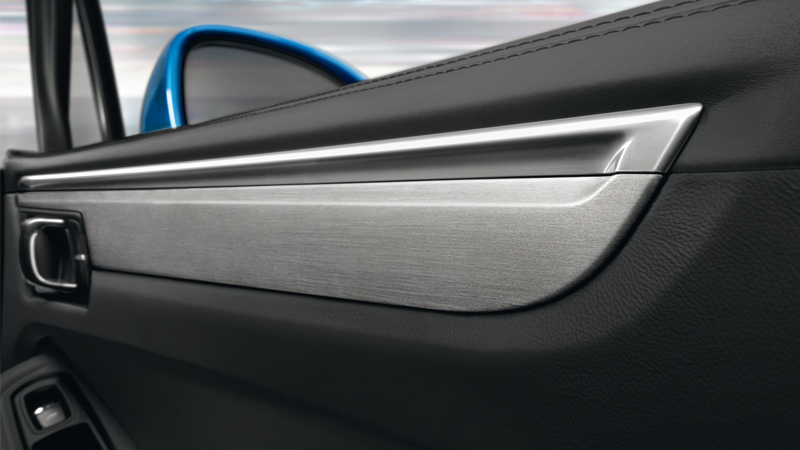

2. Door line

All components belonging to the side doors of

4. Exterior line

On the exterior line, robots fit the front and back windows and bond them into place. In addition, the

5. Engine pre-assembly

In this area, gear transmissions and components such as a/c compressors, generators, starters and servo-pumps are attached to the engines delivered. The engines are then subjected to meticulous quality control. If they pass, they are taken to the “engagement”. Engagement here means that the completed engine-transmission unit is placed onto the front axle of the vehicle.

6. Marriage

Following work on the exhaust system, axles and steering, the vehicle is ready for “marriage”, one of the most spectacular steps on any vehicle assembly line. Here, an automated guided vehicle system (AGVS) places the completed drivetrain underneath the associated vehicle body and bolts it firmly into place. In this way, the engine, chassis and body are virtually “married”. In a final step the tailpipes are installed.

7. Engine wiring

All systems are connected here to get the vehicle ready for subsequent filling. Among the systems connected in this step are the brake lines on the front and rear axles, the fuel pipes and the air line components for the pneumatic springs. The rear lettering is also fitted at this station.

10. Test line

In the test bay, the vehicle is placed on its wheels for the first time. After the programming of various control devices comes another exciting moment: the engine is started for the first time. Further steps include some final chassis and headlight tuning and the calibration of the driver assistance systems. The wheel alignment is measured with tracking cameras and adjusted manually. A steering wheel balance guarantees the straight-ahead position of the steering wheel. On completion of these steps, the vehicles are then taken to the chassis dynamometer for a driving simulation at a maximum speed of 120 km/h for a total distance of 1.5 kilometers.

11. Test drive and final inspection

As every

Fuel Consumption and Emissions

13,2 - 12,8

l/100 km

298 - 290

g/km

Panamera Turbo S (WLTP)*

Fuel consumption/Emissions (WLTP)*

Fuel consumption combined* (model range): 13,2 - 12,8 l/100 km

CO₂ emissions combined* (model range): 298 - 290 g/km