The body shop Panamera

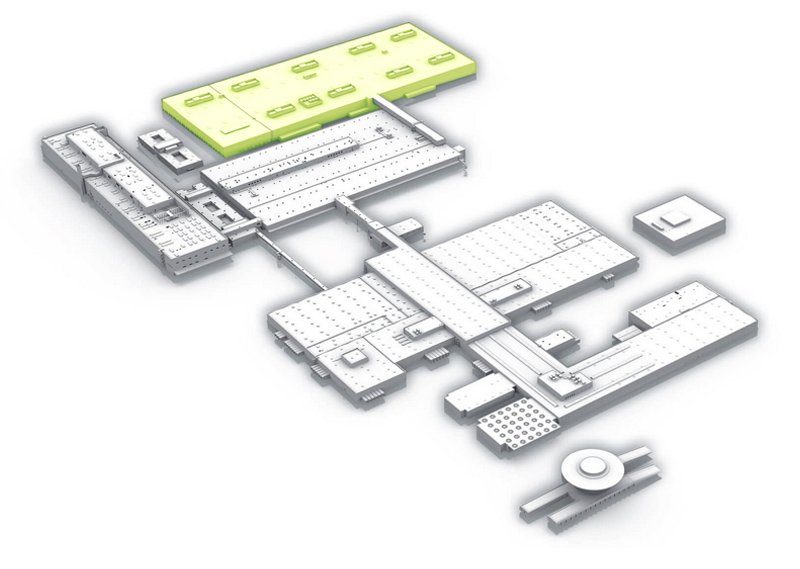

Innovative joint technologies, multi-material mix and large-scale use of aluminium: The body shop at the Porsche plant in Leipzig is one of the most modern and innovative facilities of its kind in the automotive industry.

A total of about 500 robots and some 200 employees per shift work here to produce the new generation of the Panamera based on the flexible Modular Standard Toolkit (MSB) with a vertical range of manufacture of more than 90 per cent. Body specialists employ the materials with the best properties for the job. For instance, the complete outer shell of the new Panamera is made exclusively of aluminium. “Overall, the body consists of 45 per cent aluminium.

Beside the high aluminium content, the production technologies are setting new standards. The body is made up of around 430 individual parts joined together using mechanical and thermal processes. These processes employ cutting-edge technologies. A total of 600 flow-drill screws are fitted in each body produced. Flow-drill screws tap the threads required themselves and attach steel to aluminium in an optimal manner. Other processes used include punch riveting, aluminium laser beam welding and clinching.